TERMWAY GERMANY

Add: 18 An der Schlierbach,

36132 Eiterfeld,Germany

global marketing center:sales@termway.com

global technical support center:

tech@termway.com

Tel: 0049(0)6672-918 0088

Fax: 0049 (0)6672- 918 0089

TERMWAY CHINA

Beijing Factory:NO.15 Bulding,lianDong U Valley Industrial Park,Tongzhou District,Beijing,China

Tel:400-688-1964

E-mail:bj@termway.com

Shenzhen Office

Shenzhen Office: Room 506,JICHENG Dasha,FuYong,Bao'an District,Shenzhen,China

Tel:18901351975

E-mail:sz@termway.com

|

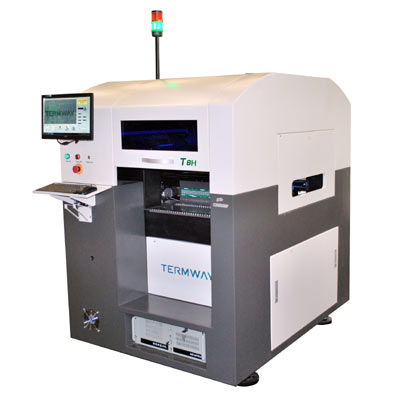

Automatic vision SMT mounter

Automatic high precision pick and place machine TP50V-II

hotline:400-688-1964

Detailed introduction

Automatic high precision pick and place machine TP50V-II

Product Description:

Product Description:TP series is a fully automatic vision SMT pick and place machine, it can mount a variety of components through the vacuum nozzle can be mounted .it is the most cost effective automatic placement equipment on recently market.This machine is suit for most of the SMD components, such as 0402,SOIC,PLCC and QFP IC; With the vision position system, meet the needs of mounting high precision 0.5mm of QFP IC or BGA . Beside the standard circle reference point, the square ,which is not the PCB solder paste screen printing pad ring perforated pad, can also be as a reference point to know.

Key Word:Automatic,high,precision,pick,

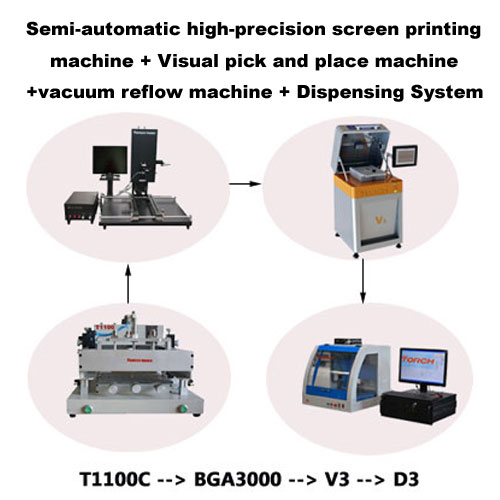

Related products

|